Medellin, Colombia

Our suppliers

We work with a local Colombia tannery to produce an innovative "wet-white" tanned leather. Like vegetable-tanning, wet-white tanning is chrome-free. It also 40% less water than conventional tanning and reduces the amount of toxins and minerals in wastewater by up to 80%, meaning wastewater can easily be recycled and reused in the production process.

Additionally, we source from LWG-certified tanneries in the region.

OUR FACTORY

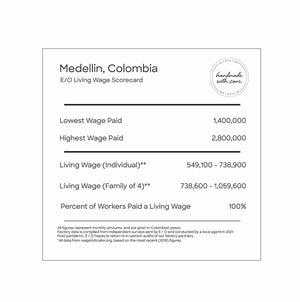

We partner with a single factory in Medellín, Colombia. Our partners are chosen carefully to ensure they pay living wages and provide safe and stable working conditions. In our Colombia factory, employees earn 1.5x-3x the minimum wage.

The lowest wage paid is 32%-89% above the average family living wage for the region based on data from wageindicator.org.

Working conditions

Our factory in Colombia is small and tight-knit, and committed to maintaining a supportive community through activities that promote a positive work environment. They have established protocols in place for workplace safety, harassment, and fair labor practices. Additionally, they are committed to continuous improvement in their efforts.

Workers adhere to a 5-day work week in Colombia, with a maximum of 46 hours.

Our packaging

We eliminated the need for a traditional shoe box in Colombia. We ship our production without plastic in our signature gingham tote bag - made using 100% recycled materials & sewn by hand in a small women-owned workshop.